Case Study: Eliminating Downtime and Blockages with Perfecta® Limitless Plus

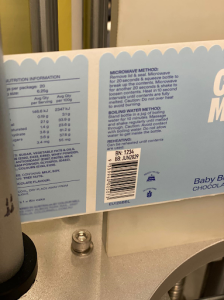

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A leading bakery company produces a wide range of pastries that are frozen immediately after production. Accurate and durable

Background A customer required high quality printing a barcode and product details on their production line running at over 100m

When evaluating polymer thermal inkjet technology it is imperative to test the inks dynamically, rather than current static methods, given our inks are measured by a different set of performance criteria that reflect actual production lines, not test laboratories.

A series of test methods have been developed to test each element of the polymer thermal inkjet inks.

|

Test

|

Description

|

Information

|

|---|---|---|

|

Open Time

|

Intervals between print activity

|

1, 2, 3, 6, 10, 15, 25, 40, 60 & 90 minutes tested

|

|

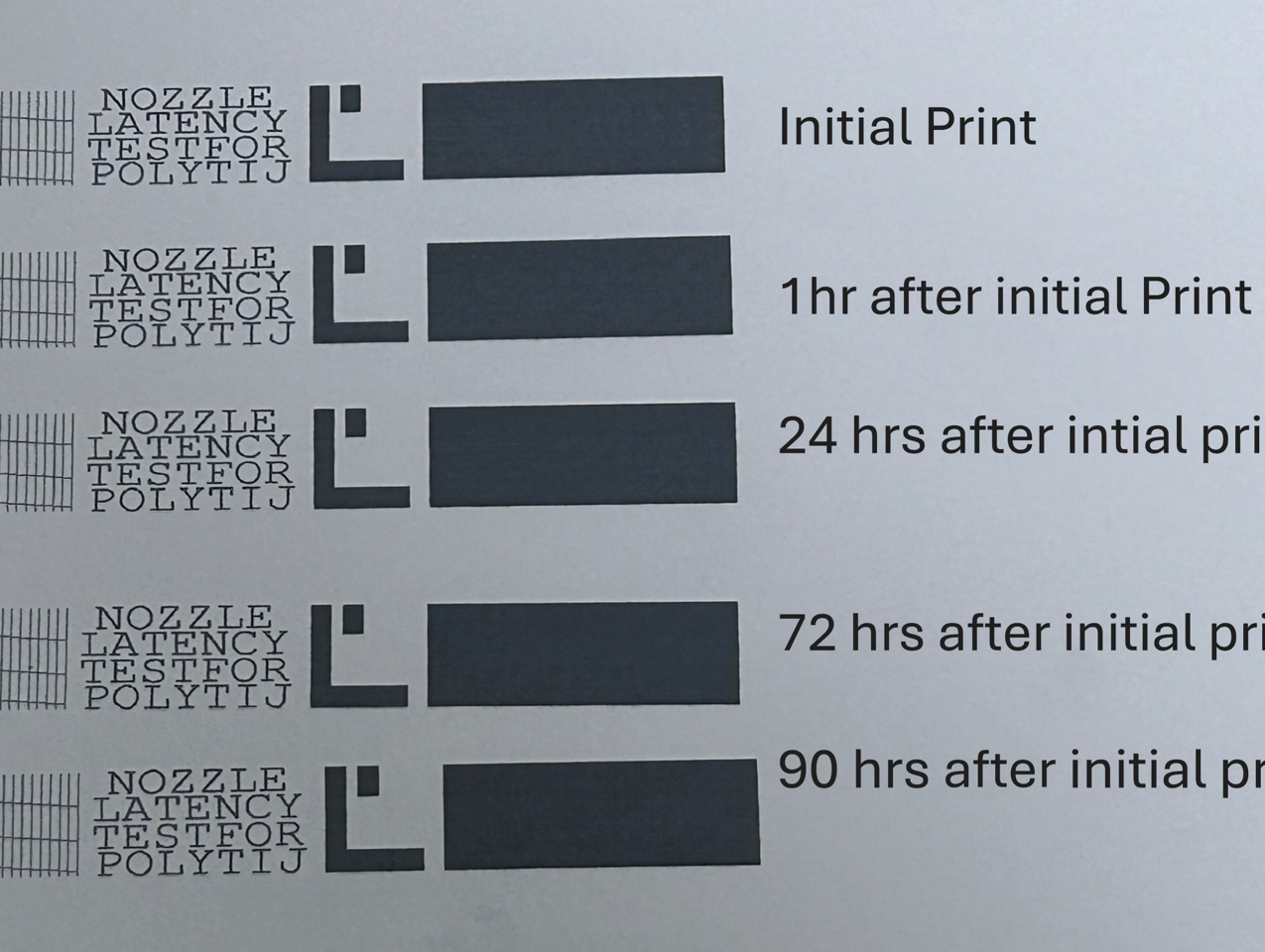

Printhead Recovery

|

Intervals between print activity

|

15 mins, 30 mins, 8hrs, 18hrs, 24hrs, 72hrs

|

|

Dry Time

|

Time for ink to dry

|

Time for ink to dry when applied to various substrates

|

|

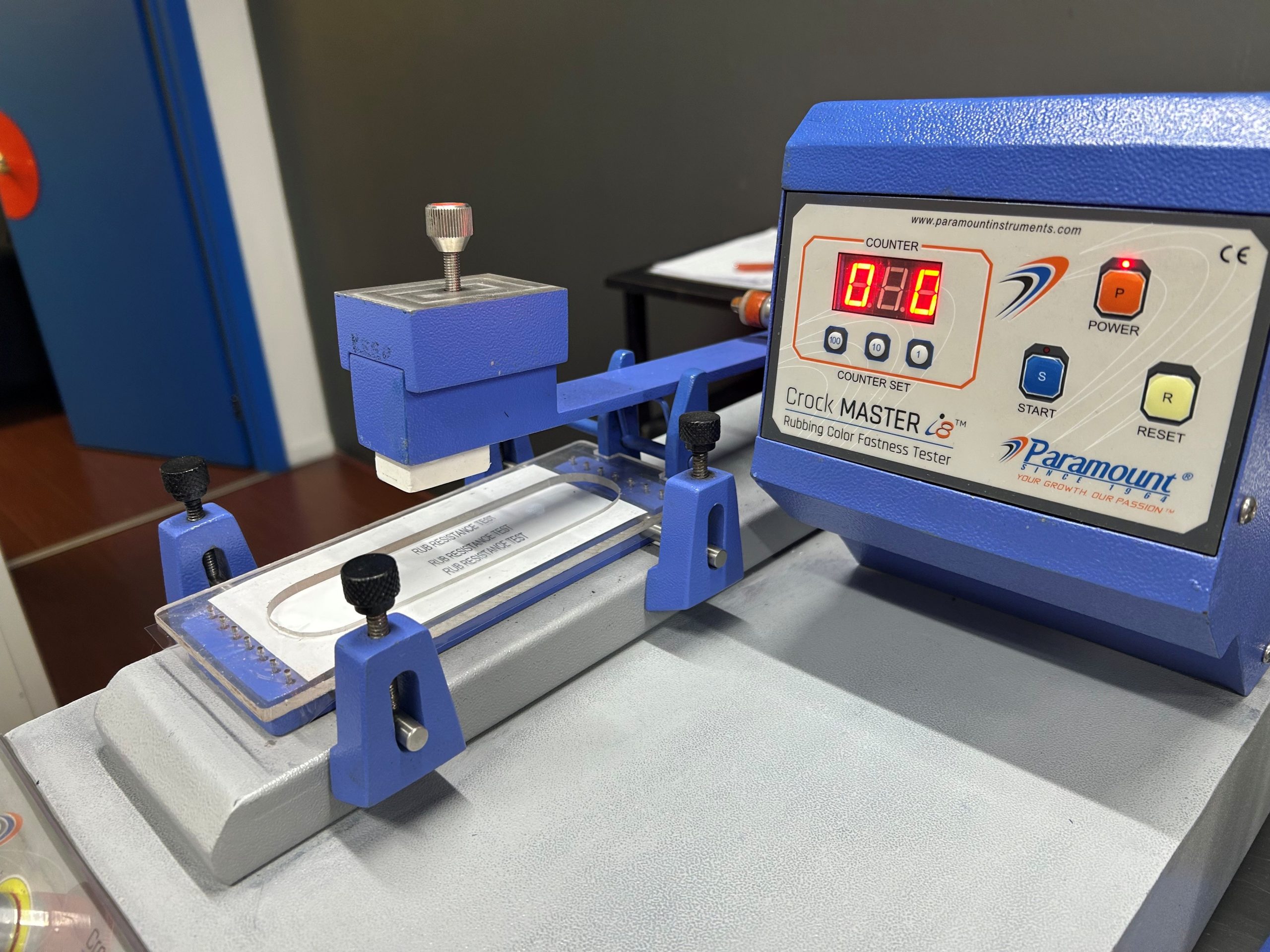

Rub Resistance

|

Resistance to ink rub off

|

Number of mechanical rubs required for printed text to be rub off when applied to various substrates

|

|

Optical Density

|

Darkness on various substrates

|

Use of Spectrophotometer to measure results

|

|

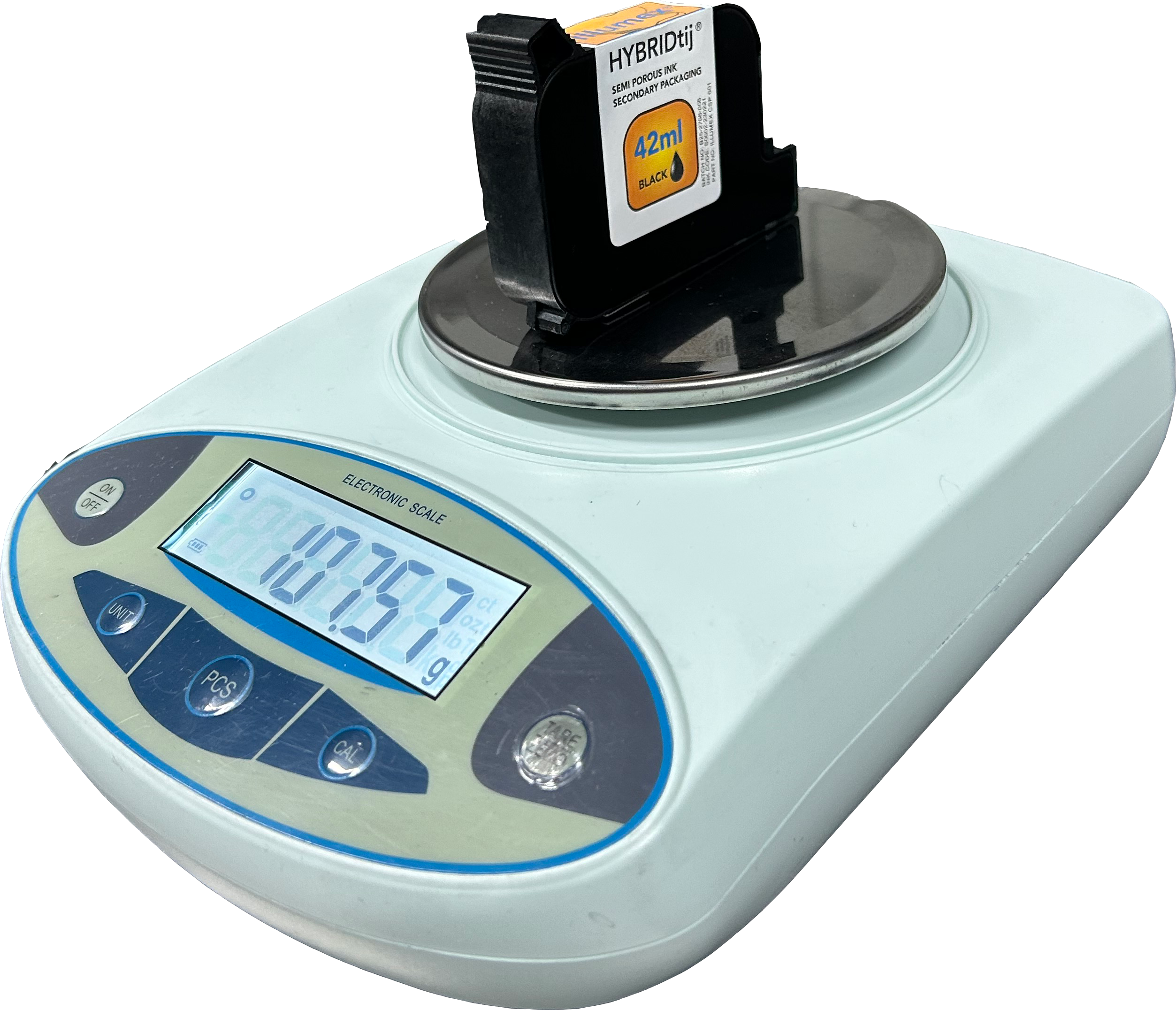

Ink Delivery Volume

|

Print at various intervals

|

Cartridge capacity volume of usable ink

|

|

Temperature Stability

|

Exposure of ink to cycle of temperature extremes

|

Ink printing capability after temperature cycles to determine shelf life expectancy of the ink

|

Test if Your Materials Are Ready for Inkjet Printing

Before starting a production run, it’s important to know whether your packaging materials will hold ink properly. That’s exactly what our Inkjet Receptive Kit is designed to help you do.

This kit helps you check if your surface (like plastic, foil, or film) is suitable for our polymer thermal inkjet inks. It shows whether the ink will stick well — so you don’t waste time, ink, or materials.

This simple test helps you catch issues before they happen — so you can print with confidence, reduce waste, and get the best possible results.

X-rite spectrophotometersallow us to measure a variety of substrates used in the FMCG market globally. Spectrophotometers achieve consistent and accurate colour measurement.

Full optical density reports are provided for polymer thermal inkjet technology printed on benchmark materials i.e. 80g Kraft paper, clear & coated PET film.

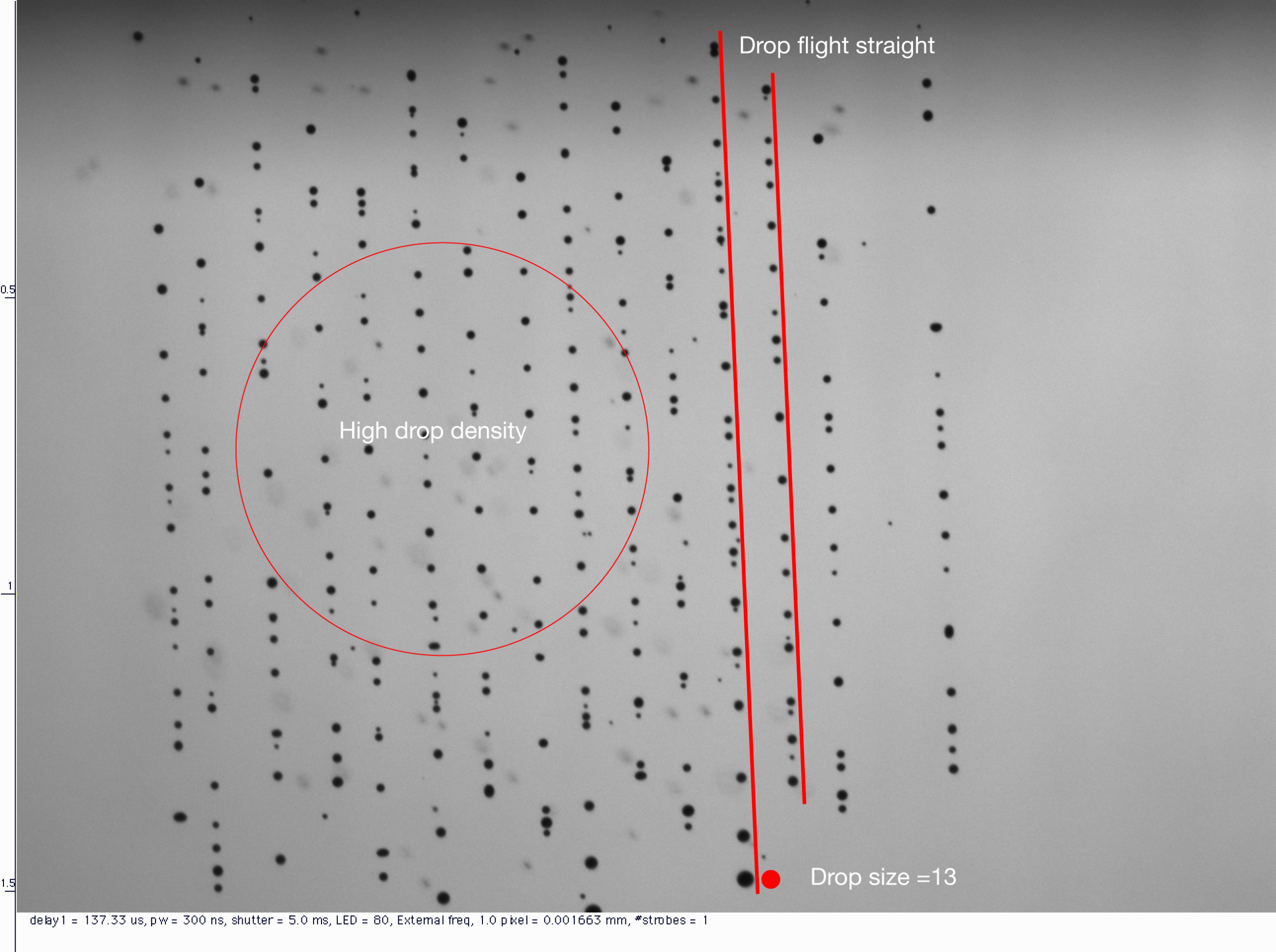

With a single drop, a drop-in-flight analyser can measure trajectory, velocity, average radius, and volume. Thus, we can detect uneven ink density or uneven colour quality caused by inaccurate dot placement or varying dot density.

By utilising drop-in-flight analysis, we are able to optimise polymer thermal inkjet technology to maximise the printability of the ink when printing text, barcodes, or logos.

Many TIJ inks dry out quickly due to poor kogation (gradual and inevitable degradation), causing nozzle blockages that ruin printer cartridge uptime. POLYtij® or polymer thermal inkjet technology uses advanced rheologies which incorporate polymer resins that stay primed and stable inside the printhead—even when idle—a breakthrough we call intervention-free technology.

With optimised ink delivery, the HP TIJ2.5 printers minimise ink usage while maximising print quality and longevity, resulting in cost savings without compromising performance.

Polymer thermal inkjet technology utilises polymer resin; as such, we have an extremely stable ink architecture. The inks are subjected to extended periods of freeze/thaw and high-temperature testing in controlled environments to accelerate the assessment of temperature stability.

By utilising a drop-in-flight analyser and barcode verifier, we can optimise the performance of polymer thermal inkjet technology for the printing of high-quality 1D and 2D barcode symbologies on a wide variety of substrates.

The drop-in-flight analyser captures clear images of single drops in flight. The barcode verifier enables us to accurately scan the 1D and 2D barcodes and ascertain the overall printability of the inks on the substrates.

Use our interactive map Below to locate an authorised DIT distributor in your region. Click on a country to see available suppliers and contact details.

Looking for us? We’re just around the corner! Connect with our team to learn more about our services near you.

We’re here to help! Reach out, and we’ll provide the guidance and support you need.

Got questions? We’ve got answers! Contact us for any inquiries or more information.