Case Study: Eliminating Downtime and Blockages with Perfecta® Limitless Plus

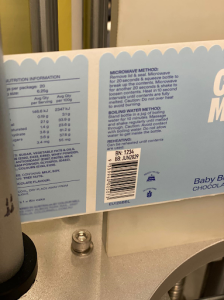

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A leading bakery company produces a wide range of pastries that are frozen immediately after production. Accurate and durable

Background A customer required high quality printing a barcode and product details on their production line running at over 100m

At Digital Ink Technologies, we’re not just in the business of ink—we’re in the business of innovation.

QR codes are two-dimentional computer-generated images. They are used by brands to communicate with consumers, enabling links to consumer information & promotions. The consumer simply aims their smart device at the QR code, and the relevent application deciphers the code and takes action e.g. connecting to a webpage

Data matrix codes are compact two-dimensional barcode symbols, made up of square modules. They are read by 2D imaging scanners or vision systems. Data matrix is popular for marking smalll items such as fresh produce.

By 2027, all retailers are expected to be able to scan 2D barcodes at checkouts. They will replace the traditional linear EAN or UPC bar codes we have known since the 1970s. Woolworths in Australia is ahead of the game and is already implementing 2D barcodes on some products. Woolworths are already scanning QR codes at checkouts. Other large retailers will follow.

There’s no need to panic as we can quickly create your 2D barcodes.

illumex ® thermal inkjet printers, already with the inbuilt ability to printer ID & 2D barcodes are well positioned to support industry and provide a low cost alternative to traditional methods.

2D Barcodes condense a wealth of information into one scannable QR code, slashing printing expenses and boosting product interactivity. They offer more capability than linear barcodes. They are gateways to multimedia experiences as they can connect to videos and webpages and enhance your customers’ experience and information about your product.

Scanning a 2D barcode with a smartphone enables consumers to access essential details such as allergens, nutritional content, recycling, sustainability, and information alongside various web engagement activities, all facilitated by the 2D digital link. This is much more flexible as retailers can use it for point-of-sale pricing, inventory management, product recalls, and numerous supply chain activities, enabling customers to see more about the product and company. So it’s goodbye to cluttered packaging!

A traditional linear barcode image (EAN or UPC format) contains only the 12 or 13-digit barcode number (GTIN).

When a 2D Barcode is scanned at the Point of Sale (POS), it functions like a traditional barcode, providing data about prices and inventory. However, when a consumer scans the 2D barcode with their mobile device, it leads them to rich product content or a brand-specific webpage. The 2D code can connect users either to a simple product information page or to a wide variety of other pages and product information.

The black-and-white striped 1D barcode has been a hallmark on product labels since 1974. Most consumer products carry a UPC or EAN barcode with a unique GTIN for item identification and price look-up at retail checkouts. For 50 years, this innovation has been a cornerstone across industries, reliably delivering key information such as product type, color, size, and price for inventory management and product tracking. But, as consumer needs shift towards greater traceability and interactive experiences, it’s clear that these linear stripes are reaching their limitations.

The global move to 2D barcodes is more than a technological evolution — it’s about ensuring businesses are ready for the future. With 2D barcodes set to become the gold standard, upfront investments and temporary workflow disruptions are inevitable.

As manufacturers and retailers work towards the 2027 milestone, they must invest in new scanning technologies to support both traditional and 2D barcodes. With 2D barcodes containing more data, robust data protection systems must also be in place to safeguard sensitive information. Additionally, training staff on new software and equipment will ensure a hassle-free and smooth integration with existing systems.

High-quality 2D barcodes demand advanced printing solutions, and choosing the right coding and marking technology is crucial for ensuring accuracy and efficiency.

Barcodes facilitate accurate inventory tracking and management, helping retailers to monitor stock levels and optimize supply chains.

Barcodes are essential for scanning products at the point of sale, enabling retailers to record price and inventory data.

Barcodes help track product origin, production details, and expiry dates, enhancing supply chain transparency and food safety.

Barcodes enable efficient and accurate product recalls by identifying specific products for removal.

2D barcodes like GS1 QR codes allow for the sharing of additional product information and can be used to link to digital content.

Polytij® is the world’s most advanced polymer thermal inkjet technology, engineered to outperform conventional solvent-based inks. Designed for FMCG, pharmaceuticals, and industrial packaging, Polytij® delivers: