Case Study: Eliminating Downtime and Blockages with Perfecta® Limitless Plus

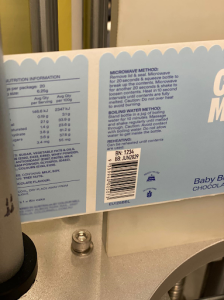

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A leading bakery company produces a wide range of pastries that are frozen immediately after production. Accurate and durable

Background A customer required high quality printing a barcode and product details on their production line running at over 100m

HPTIJ2.5 inkjet printing technology revolutionises how the FMCG, Pharmaceutical, and General Purpose industries approach high-speed, high-resolution marking and coding.

The thermal inkjet printing process operates through a precise mechanism where ink cartridges within the printer heat the ink to temperatures up to 300°C. This intense heat causes the ink to boil and form a vapour bubble, expanding its volume. The formation of this bubble generates pressure that propels ink droplets out of the nozzle with high accuracy onto the substrate.

Once the ink droplets make contact, they cool rapidly, returning to a liquid state and creating sharp, detailed prints. As the vapour bubble collapses, a vacuum is created, drawing new ink into the nozzle for the next droplet ejection. This cycle allows for fast, efficient printing without compromising on quality.

HP Thermal Inkjet Technology (HPTIJ2.5) drives the performance of HP45si & HP45A print cartridges. The result is high-resolution printing (up to 600 dpi) for sharp text, crisp barcodes, and graphics.

Digital Ink Technologies Pty Ltd is the only HPTIJ2.5 ink filler that offers the five pillars of inks needed for FMCG & Pharmaceutical industries. Our wide variety of inks —including Thermochromic, Hot Ink Printing and Food grade inks and unique intervention free fast drying inks —offer the right solution for your business.

Maintain high quality and high productivity with high-performance Polymer Thermal Inkjet Inks. Digital Ink Technologies Pty Ltd’s unique HPTIJ 2.5 inks supports a wide variety of applications and substrates. Each ink accentuates certain performance characteristics such as substrate coverage, fast drying time, or long decap time.

Every Digital Ink Technologies Pty Ltd print cartridge must meet strict quality standards. All Digital Ink Technologies Pty Ltd inks are subject to a battery of tests to prevent problems that degrade image quality such as microscopic contaminants that can clog printhead nozzles (kogation). Count on consistent printing performance and reliable results.

Save time, improve productivity, and lower operating costs. Self contained, customer-replaceable unique POLYtij® Intervention free inks in HPTIJ2.5 cartridges eliminate time-consuming and routine maintenance and deliver a fresh printhead with each cartridge replacement. Proven HPTIJ2.5 Thermal Inkjet Technology enables low-cost, efficient ink usage.

When you choose our HPTIJ2.5, you’re investing in:

Traditional TIJ inks dry out quickly mainly due to poor kogation (Gradual and inevitable degradation), causing nozzle blockages that ruin printer cartridge uptime. POLYtij® uses advanced rheologies which incorporate polymer resins that stay primed and stable inside the printhead, even when idle — a breakthrough we call intervention free technology.

These levels define our product tiers — from Adhesion+50 to Perfecta Limitless Plus, each suited to different industrial demands.

Absorption occurs when molecules pass into a bulky material. An everyday example of this is a paper towel absorbing water – imagine water evenly permeating a paper towel as it soaks it up. The ratio of absorption depends on factors like concentration levels of the substance being absorbed, exposed surface area, and pressure.

Adsorption is a process in which atoms, ions, or molecules from a substance adhere to a surface (of the adsorbent). Our unique POLYtij® inks utilise polymer resins which are bonding agents and can form strong bonds with various substrates such as metals, plastics, wood, glass, ceramics and composite materials.