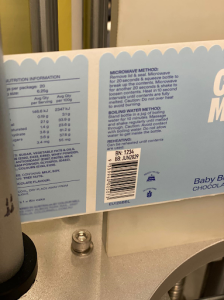

Case Study: Eliminating Downtime and Blockages with Perfecta® Limitless Plus

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A leading bakery company produces a wide range of pastries that are frozen immediately after production. Accurate and durable

Background A customer required high quality printing a barcode and product details on their production line running at over 100m

At Digital Ink Technologies, we’re not just in the business of ink—we’re in the business of innovation.

Traditional TIJ inks dry out quickly mainly due to poor kogation (Gradual and inevitable degradation), causing nozzle blockages that ruin printer cartridge uptime. POLYtij® uses advanced rheologies which incorporate polymer resins that stay primed and stable inside the printhead, even when idle — a breakthrough we call intervention free technology.

These levels define our product tiers — from Adhesion+50 to Perfecta Limitless Plus, each suited to different industrial demands.

Not all TIJ cartridges and perform the same way.

HP45si solvent cartridges filled with POLYtij ® Perfecta Intervention free inks outperform inferior IUT and Uniplas cartridges across a number of key performance criteria that ultimately will impact on the reliability of your thermal inkjet printers impacting your production uptime.

Let us show you why HP45si cartridges are the choice for maximise production uptime.

Ink puddling, or build up of ink on the cartridges nozzles impacts greatly on the reliability of the cartridge and the need for regular maintenance by production staff. The less intervention means more reliable operation of your thermal inkjet printers and production uptime

To maximise production uptime and minimise production costs it is imperative that TIJ cartridges are able to utilise as much of the ink in the cartridges as possible. Less than 95% ink delivery volume effectively means that you are “losing” ink per cartridge which effects the real value of the cost of each cartridge.

Kogation, or better known as ink nozzle blockages occurs when either the impurities of the ink eventually block the nozzles or the cartridge internal resistors do not operate correctly (Potentially damaged by the ink or blocked by the build up of dye on the resistor)