Background

A leading bakery company produces a wide range of pastries that are frozen immediately after production. Accurate and durable date coding was essential for traceability, food safety compliance, and customer confidence.

The Challenge

Once frozen, the pastries were packaged and shipped to distribution centers. During transport, the products would often begin to partially defrost, creating condensation inside the packaging. As cartons and packs rubbed together in transit, the printed manufacturing dates were smudged or erased.

This caused:

- Loss of critical product traceability.

- Risk of non-compliance with food safety requirements.

- Increased waste and customer dissatisfaction.

The Solution

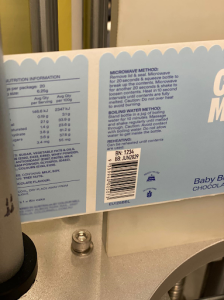

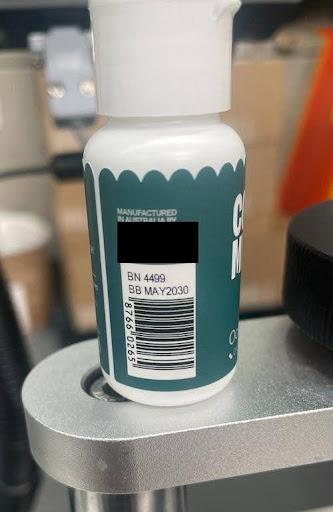

The bakery adopted Perfecta® WR ink, a water-resistant formulation designed to withstand condensation and handling. Perfecta® WR provided:

- Excellent adhesion to packaging surfaces, even in cold environments.

- Water-resistant print to condensation in refrigerated conditions.

- Durability against smudging and rubbing during transport.

- Consistent, legible date codes from production through to delivery.

The Results

By switching to Perfecta® WR, the bakery achieved:

- Reliable date coding that remained intact despite defrosting and condensation.

- Improved compliance with food safety and traceability standards.

- Reduced product waste caused by unreadable codes.

- Increased customer confidence in product quality and reliability.

Conclusion

Perfecta® WR resolved a critical issue for the bakery, ensuring that manufacturing dates remained clear and durable throughout freezing, transport, and handling. This solution protected traceability, compliance, and brand integrity across their distribution chain.