Background

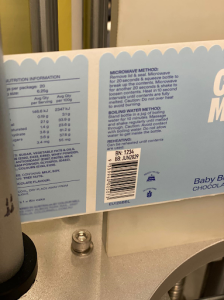

A customer required high quality printing a barcode and product details on their production line running at over 100m per minute. At these speeds, clarity and barcode readability are critical to ensure that printed text remains legible and the barcode is compliant with industry standards.

The Challenge

The customer’s existing ink could not keep pace with their production requirements. While it printed acceptably at lower speeds, at 120m/min and above the barcode did not scan and became faint and unclear, leading to poor readability and an increased risk of rejected product.

The Solution

To address this, we introduced HYBRIDtij® ink, a formulation specifically designed for high-speed barcode printing applications on porous and semi-porous materials.

HYBRIDtij® provides:

- Excellent contrast to maintain sharpness even at maximum throughput.

- Barcode readability to a variety of substrates, reducing smudging and fading.

- Reliable performance at speeds exceeding 120m/min, ensuring consistent quality without production slowdowns.

The Results

By switching to HYBRIDtij® ink, the customer achieved:

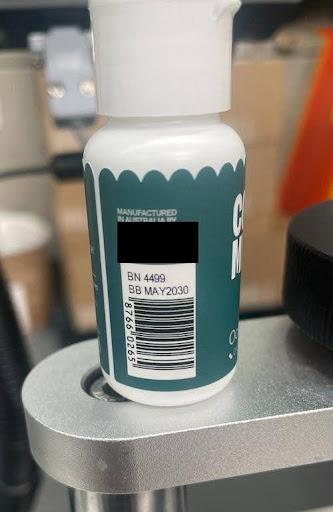

- High speed printing crisp, clear text and barcodes.

- Improved print quality and legibility, even under demanding conditions.

- Confidence in line efficiency, with no need to reduce speed to maintain readability.

- Durability, if the label on the product was in the incorrect position the ink would adhere to it and not rub off.

Conclusion

HYBRIDtij® enabled the customer to meet their high-speed production goals without sacrificing print clarity or adhesion. This case highlights how purpose-designed ink formulations can overcome the limitations of standard inks, delivering both speed and quality