Background

A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements as part of their production process. The need for uninterrupted production was vital; however, recurring stoppages for setup changes and servicing made this difficult to achieve.

The Challenge

Whenever the production line was stopped, the customer faced two recurring issues:

- Downtime during stoppages – Clearing blockages took 4–5 minutes each time.

- Cartridge blockages on restart – Ink dried on the printhead during stoppages, causing faulty print quality. This meant operators had to intervene before production could resume, reducing efficiency and consistency.

- Print quality – The customer could never consistently achieve a high-quality print. These interruptions led to wasted time, increased operator involvement, and if left unnoticed product rejection from customers.

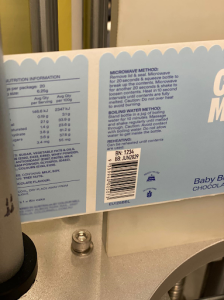

Previous Print Quality

The Solution

To address downtime issues, the customer adopted Perfecta® Limitless Plus, a high-performance ink engineered with a 72-hour open time. This innovation prevents nozzle blockages and ink drying during extended pauses in printing.

The Results

With Perfecta® Limitless Plus, the customer experienced immediate improvements:

- No more blocked cartridges after stoppages.

- Smooth restarts – even after the line was down overnight or across weekends.

- Zero operator intervention required to restart printing.

- Significant reduction in downtime, with uninterrupted, high-quality barcode and address printing.

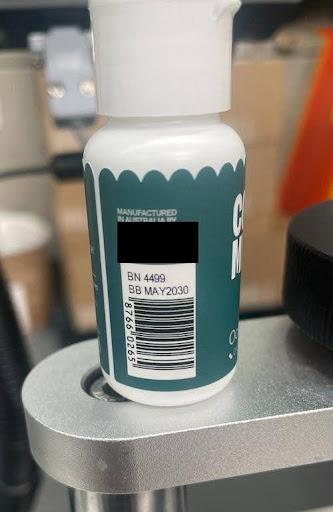

Print Quality with Perfecta® Limitless Plus

Conclusion

Perfecta® Limitless Plus provided a breakthrough for the customer by removing the risk of ink drying and cartridge failure. With its 72-hour open time, print lines can be stopped overnight or even across weekends, and resumed with immediate, reliable output no purging or rework required.