The Challenge

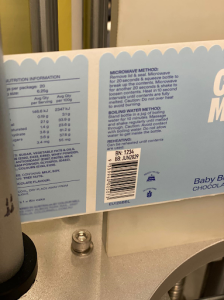

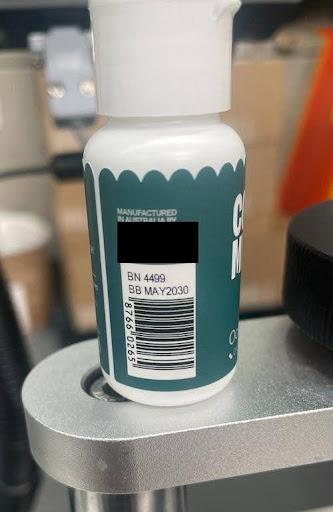

A customer was experiencing difficulties when printing a Data Matrix GS1 barcode directly onto their packaging. Although the initial print appeared sharp, within seconds the ink began to spread across the surface. This caused the print to blur and become difficult to read, compromising both legibility and barcode scan reliability.

The Solution

To address the issue, the customer adopted Perfecta® Limitless Barcode ink. Unlike conventional inks that can sit on the surface and migrate, Perfecta® Limitless Barcode was specifically formulated to contract on contact with the surface. This unique property ensures the print remains crisp and well-defined immediately after printing.

The Results

With Perfecta® Limitless Barcode:

- Scannable and reliably printed Data Matrix GS1barcode.

- Prevented ink spreading on the surface.

- Print quality improved significantly, ensuring compliance with packaging and traceability requirements.

Conclusion

By switching to Perfecta® Limitless Barcode ink, the customer overcame the challenge of ink spreading. They achieved sharp, durable, and reliable barcode prints, demonstrating how tailored ink solutions can directly enhance production quality and efficiency.