Case Study: Eliminating Downtime and Blockages with Perfecta® Limitless Plus

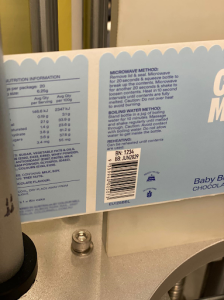

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A leading bakery company produces a wide range of pastries that are frozen immediately after production. Accurate and durable

Background A customer required high quality printing a barcode and product details on their production line running at over 100m

At Digital Ink Technologies, we’re proud to offer our exclusive POLYtij® polymer thermal inkjet technology, engineered to outperform conventional solvent-based inks in HPTIJ2.5 industrial printers.

Unlike cheaper dye-based or solvent inks that rely on absorption, POLYtij® inks are formulated with polymer resins — advanced bonding agents that adhere to surfaces through adsorption, forming durable connections on materials like:

These resins deliver unmatched adhesion, resilience, and versatility across the toughest packaging conditions.

Whether your production line stops for 1min, 30 minutes or 3 days, POLYtij® picks up right where it left off — no operator maintenance, no quality loss.

Our intervention-free inks deliver:

first print perfect, even after days of idle time

You just don’t touch the cartridge, period!

Ink chemistry is high stable , offering extended ink life

in all in cold, humid, or water-exposed environments

Traditional TIJ inks dry out quickly mainly due to poor kogation (Gradual and inevitable degradation), causing nozzle blockages that ruin printer cartridge uptime. POLYtij® uses advanced rheologies which incorporate polymer resins that stay primed and stable inside the printhead, even when idle — a breakthrough we call intervention free technology.

These levels define our product tiers — from Adhesion+50 to Perfecta Limitless Plus, each suited to different industrial demands.

Absorption occurs when molecules pass into a bulky material. An everyday example of this is a paper towel absorbing water – imagine water evenly permeating a paper towel as it soaks it up. The ratio of absorption depends on factors like concentration levels of the substance being absorbed, exposed surface area, and pressure.

Adsorption is a process in which atoms, ions, or molecules from a substance adhere to a surface (of the adsorbent). Our unique POLYtij® inks utilise polymer resins which are bonding agents and can form strong bonds with various substrates such as metals, plastics, wood, glass, ceramics and composite materials.