Case Study: Eliminating Downtime and Blockages with Perfecta® Limitless Plus

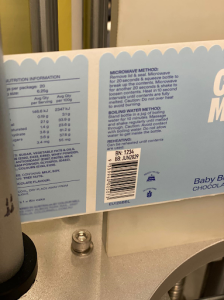

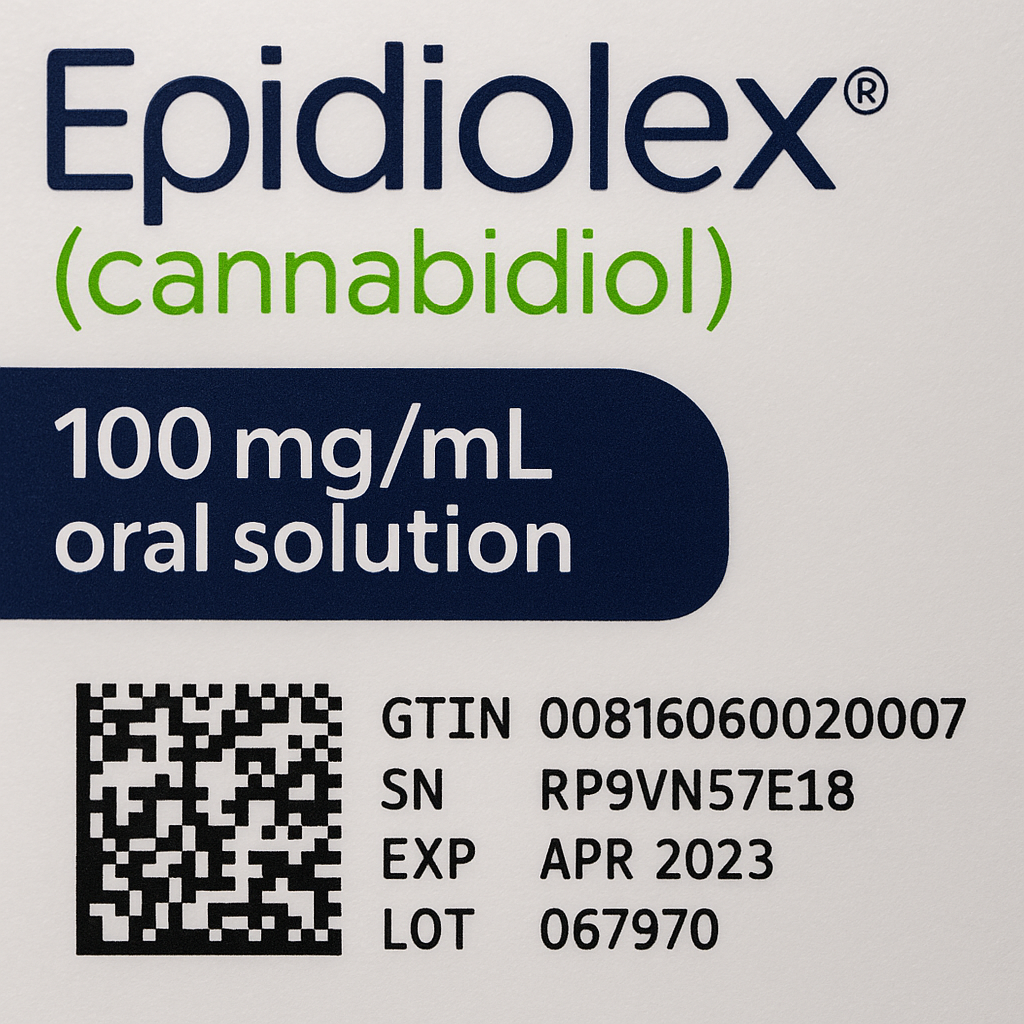

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A customer required reliable printing of a batch number and best before date for quality control and regulatory requirements

Background A leading bakery company produces a wide range of pastries that are frozen immediately after production. Accurate and durable

Background A customer required high quality printing a barcode and product details on their production line running at over 100m

When you’re coding thousands of products an hour, performance isn’t optional — it’s mission-critical. From batch codes on pharmaceutical foil to expiry dates on vacuum-sealed cheese, Digital Ink Technologies Pty Ltd delivers unique thermal inkjet solutions that redefine what’s possible with HP TIJ 2.5 printing.

At the core of our innovation is POLYtij® — a intervention-free, polymer-based ink technology that achieves superior adhesion, durability, and production uptime across even the most difficult substrates.

From food and beverage to pharmaceuticals and industrial packaging, our polymer-based thermal inkjet solutions are trusted in the world’s most demanding production environments.

Explore how POLYtij® delivers precision, uptime, and compliance across a wide range of industries.

Unstoppable production. Unmatched reliability

Where legibility meets legislation.

No Capping, No wiping, No problem!

Barcodes. Logos. Regulatory codes — high durability

Unstoppable lines. Unmatched reliability.

“Unlike other solvent inks, POLYtij® inks just keeps going. It’s our go-to ink for flexible packaging.”

— Production Manager, Leading Australian Snack Brand

Where legibility meets legislation.

“POLYtij® ink prints hold up from line to lab to logistics. That’s peace of mind for QA.”

No primer. No wiping. No problem.

Barcodes. Logos. Regulatory codes — all intact.

Unplanned downtime costs manufacturers at least 50% more today than it did five (5) years ago, due to spiraling inflation and production lines running at higher capacity.

*Source: True Cost of Downtime Report, 2023

Unplanned downtime costs manufacturers at least 50% more today than it did 5 years ago, due to spiraling inflation and production lines running at higher capacity.

Intervention free inks require no wiping, no capping or human intervention whatsover. That's genuine maximum printer performance unique to our ink technology designed to save you money.

*Senseye’s True Cost of Downtime Report, 2020

Digital Ink Technology’s next generation coding & marking inks integrate seamlessly with high-speed, high-volume production lines, delivering flawless prints, every time.

Access expert guidance from certified distributors in your region.

Get POLYtij® inks delivered quickly, minimising production delays.

Work with partners who understand your market, whether it’s FMCG, pharma, or heavy-duty packaging.